SMART REFUELING STATION SRS

"Water is the coal of the future. The energy of tomorrow is water that has been broken down by electricity. The elements of water broken down in this way, hydrogen and oxygen, will secure the earth's energy supply for the unforeseeable future." - Jules Verne came to this realisation as early as 1870 in his work "The Mysterious Island".

At a time when fossil fuels are becoming scarce and environmental protection is becoming increasingly essential for our planet, sera HYDROGEN GmbH has committed itspi-7001_04_en_infinity_piston_compressor.pdfelf to precisely this vision. With this in mind, we have developed and launched our innovative hydrogen refuelling station to take a pioneering step towards preserving our environment and doing our bit for the energy revolution. Hydrogen technology as the fuel of the future.

DOWNLOAD

Piston Compressor

DESIGN AND OPERATION

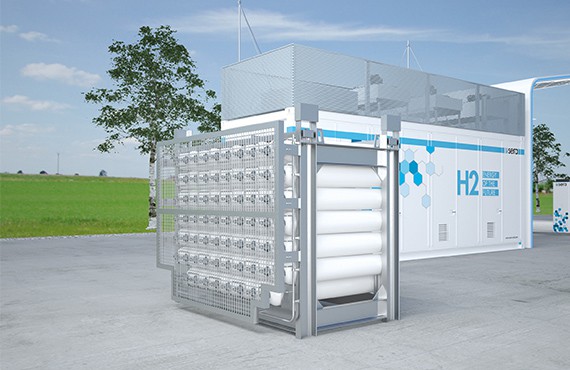

sera Technology container

The technical container is the central element of the sera hydrogen refuelling station. The modular technology container is equipped with state-of-the-art compressor systems, cooling technology, valve technology and a control system.

The hydrogen is first compressed to up to 900 bar using compressors and then stored in buffer tanks until required. The buffer storage tanks can be installed both inside and outside the technology container.

Storage solutions

We offer versatile solutions for storing hydrogen.

Among other things, with our efficient large-capacity bundles.

A large-capacity bundle is a rack containing gas cylinders. All gas cylinders in the large-capacity bundle are connected to each other via pipes and valves. This storage solution is ideal if the system is to be expanded at a later date, as any number of bundles can be placed. Even very small quantities can be stored with this concept.

Dispenser

The final step of hydrogen refuelling takes place at the dispenser unit. The filling coupling, filling hose, display and control technology are integrated in this unit. A terminal for payment can be placed separately.

The user can conveniently initiate the refuelling process via a display. A short step-by-step guide follows until the fuelling nozzle is securely attached to the vehicle's filler neck. Now the hydrogen, which is as cold as -40 °C, flows into the vehicle's hydrogen tank via the fuelling nozzle.

The dispenser developed by sera can refuel vehicles with both 350 bar and 700 bar. We offer this dispenser with one or two filling couplings.

The compressor is the "heart" of our hydrogen refuelling station.

Our metal diaphragm and piston compressors are used in our refuelling systems.

MODULAR DESIGN

Thanks to standardised modules, the hydrogen filling station can be optimally adapted to the customer's needs. Subsequent extensions are no problem.

HIGH FLOW RATE

Our innovative piston compressor enables high delivery rates. This means that frequent refuelling with high delivery rates can also be realised without any problems.

LOW-MAINTENANCE & RELIABLE

Due to the slow stroke of our compressor, wear parts are subject to little stress and therefore have a long service life.

SERVICE-FRIENDLY

Our system container has been designed so that every technical component is easy to reach. This minimises service times and guarantees smooth operation.

QUIET OPERATION

In order to be able to operate the sera hydrogen refuelling station in noise-sensitive areas, special care was taken during development to keep noise emissions as low as possible.

LOW ENERGY CONSUMPTION

The electro-hydrostatic drive and the low frictional forces of our innovative compressor technology ensure low energy consumption.

sera SYSTEM SOLUTIONS

How does the hydrogen get to the sera hydrogen refuelling station?

It's quite simple! sera offers various system solutions that cover both commercial and public applications.

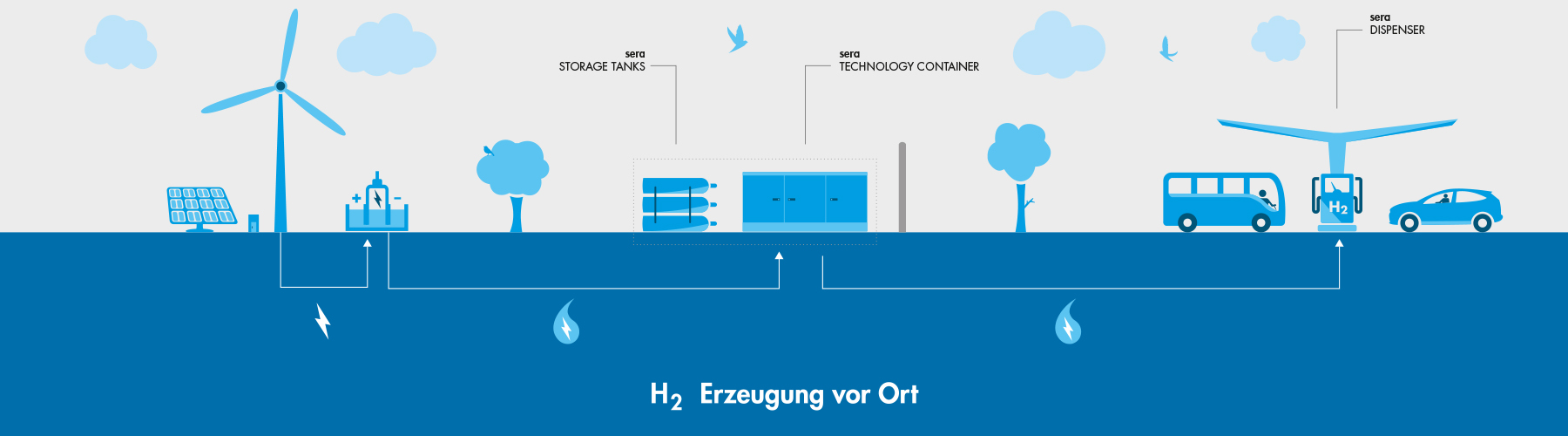

ON-SITE PRODUCTION

In this scenario, the hydrogen is produced locally by an electrolyser and fed directly into the refuelling station system. One of our innovative compressors then compresses the hydrogen to the required pressure level in order to fill it directly into the storage tanks. There it is available on demand.

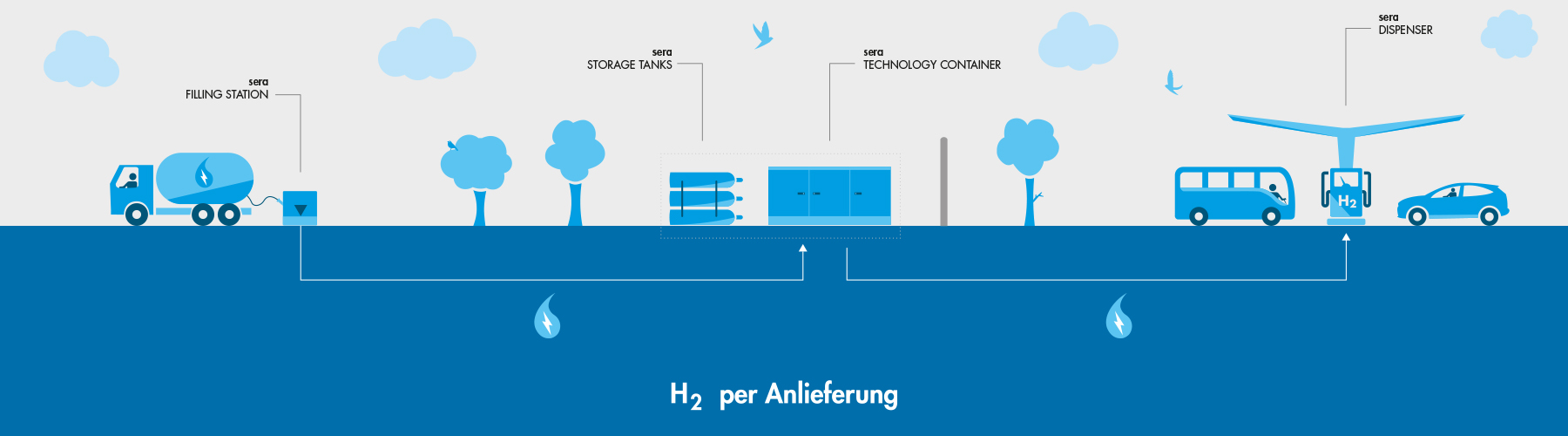

BY DELIVERY

One way of guaranteeing the hydrogen supply at the refuelling station is to deliver hydrogen by trailer. The hydrogen must be produced elsewhere and is then delivered in a trailer. The driver of the tanker connects it to the sera remote filling system and allows the hydrogen to flow into the storage tanks.

LinkedIn

LinkedIn Instagram

Instagram